Factory digitalization

Advance your manufacturing with digital innovations

Elevate efficiency

Ensure full traceability

Manage volume fluctuations

Keep up with competition in times of shifting customer demand

Market competition, ever-changing customer demand, and faster delivery expectations are placing more strain on manufacturing businesses.

Manufacturing leaders must improve their productivity, profit, and product quality, simultaneously ensuring a sustainable workplace that protects employee health and safety.

Compare your company to the competition when it comes to digitalization challenges

Future-proof your business with digitalization

Proekspert’s specialists are well familiar with digital technologies, having years of experience in software development for industrial automatics. We help manufacturers implement digitalization to improve their plant operations and create a future-proof digital enterprise.

Steps of factory digitalization

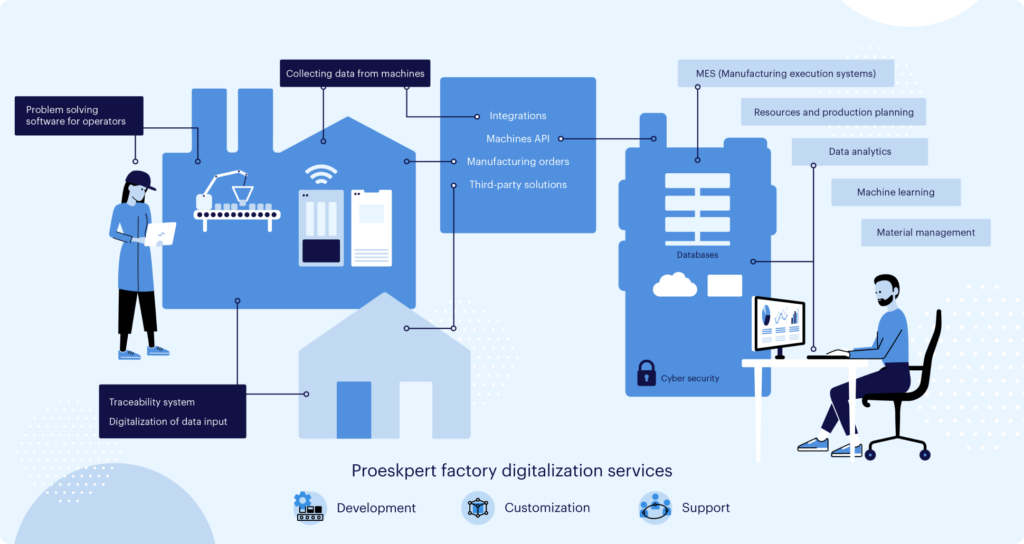

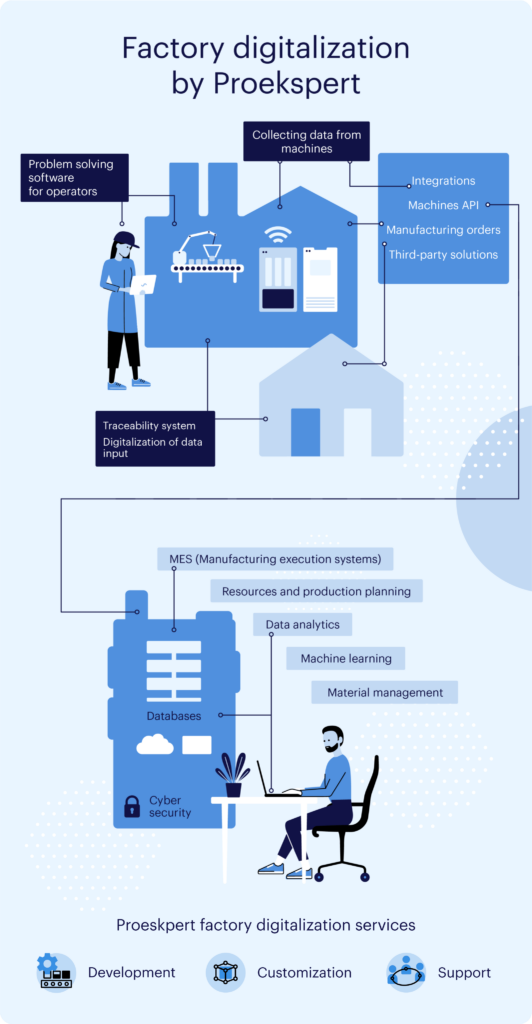

Proekspert factory digitalization services

Make paper and excel files smart

Paper documents and Excel sheets are costly, slow to file, and highly prone to human error. Proekspert helps make data available in quickly-extractable digital form, speeding decision making, decreasing costs, and gaining market advantage. Real-time reporting and monitoring through data unification enables data-driven decision making.

Connect the shop floor to the business

Proekspert centralizes factory data generated by machines, sensors, ERP, MES, quality systems, and also paper/excel-based information, to provide real-time operational visibility. We help manufacturers consolidate machine data to generate actionable insights.

Digitalizing legacy and non-smart equipment

Proekspert helps upgrade your legacy equipment retroactively. With just a couple of smart monitoring systems legacy equipment becomes a digital asset. Industrial connectivity works by opening a channel for communication and data across the machines that your business relies on for production.

Maximize the efficiency of your hardware

Do you have new equipment or a new production line in your factory? Or a fully-equipped, newly built factory? There are countless opportunities to leverage smart technologies and stop the inefficient use of expensive devices. Leave device integration to us, so you can focus on adding value.

Empower your data with machine learning

Machine learning is becoming even more prevalent as manufacturers journey toward Industry 4.0. Leverage Proekspert’s machine learning capabilities to get more value out of your data and optimize production. Proekspert helps clients understand how analytics solutions operate in a production environment, and how to choose the right one.

Third-party integrations

Manufacturing companies utilize a large array of tools, equipment, and software. Unfortunately, most tools work in silos. Proekspert helps you integrate existing equipment and tools for maximum efficiency.

Intuitive software UI/solutions for operators

Modern factory software is often complicated to use and requires training. Proekspert offers simple-to-use, custom solutions, and custom interface layers to simplify the work of operators.

Custom software

There are many solutions available for software problems, but most won’t meet your needs. Proekspert offers custom solutions that answer your specific needs.

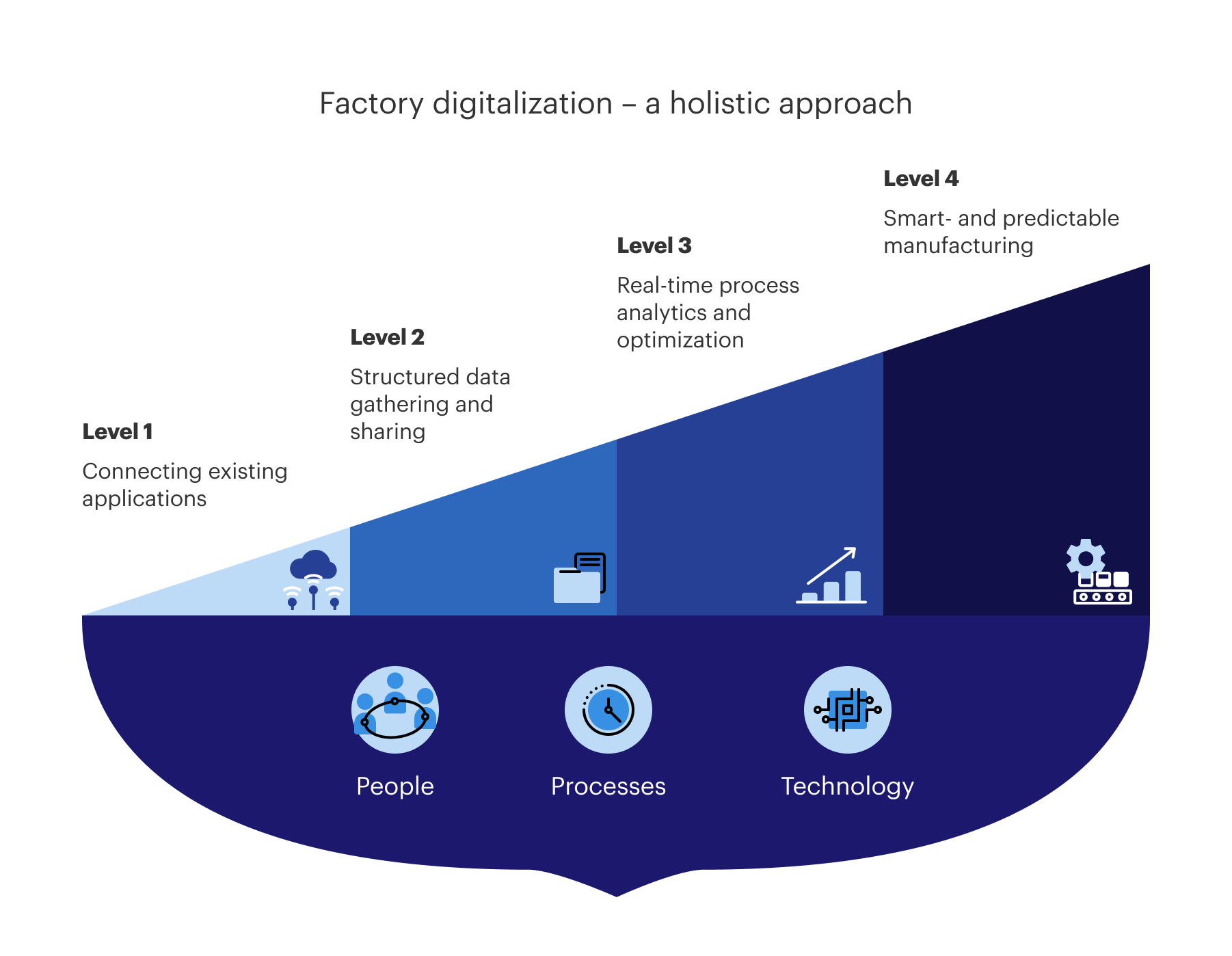

Proekspert factory digitalization roadmap

The transformation process is evolutionary, taking years, and requires adjustments across the entire organization. Proekspert sees digitalization as a four-phase process.

Mapping business needs

Understand the needs and challenges of your business, and then identify critical areas where we can introduce new solutions.

Connecting existing applications

Assess the technological requirements needed to connect your multiple systems, laying the foundation for a smart factory.

Structured data gathering and sharing

Create models for structured data gathering and sharing. At this level, a critical activity is the reduction of irrelevant information flow through increased accuracy in data collection.

Real-time process analytics and optimization

Create data-gathering models to eradicate irrelevant information and ensure accuracy of information. Aggregate the impact of collected data through real-time process analytics and optimization.

Smart- and predictable manufacturing

Prioritize smart- and predictable production methods. Know the impact in advance and guarantee profits thanks to production reliability.

Factory digitalization – a holistic approach to greater production reliability and greater profits

Underestimating the extent of the transformation required is the reason more companies fail than succeed when it comes to reaching their digitalization goals. Transformation concerns people, mindsets, processes. It is a change driven by purpose which, in turn, results in value and allows the business to evolve.

What is factory digitalization?

Factory digitalization is the combination of traditional manufacturing processes enhanced with advanced technologies. The end goal is to improve profitability through cost reductions without a loss of quality. Also improved are efficiency and competitiveness.

With the business environment becoming increasingly digital, the question is “when” a factory should digitize, not “if.”

Digitalization is not only about the use of technology and automation – it’s about how people and processes align with newer methods of achieving manufacturing productivity, safety, and reduced operating costs.

Factory digitalization is changing how products are designed, manufactured, used, and maintained. It is also transforming operations, processes, and the energy footprints of factories and supply chains.

Digitalization fosters closer cooperation between stakeholders. For example, between suppliers and customers and between employees themselves, providing new opportunities for all parties involved.

When discussing factory digitalization, the transformation process may be broken down into two areas: Smart manufacturing and Smart factories.

Smart manufacturing

Smart manufacturing utilizes connected digital products to monitor manufacturing production processes. Its goal is to identify opportunities for automating operations and use data analytics to improve manufacturing performance.

By collecting and analyzing data, manufacturing companies can make better, more informed, and smarter decisions.

Smart factory

Physical production processes are combined with digital technology enablers and data analytics to create an optimized production system.

Smart manufacturing plus the smart factory means information access, all applied using the Internet of Things.

The benefits of factory digitalization

Next-generation manufacturing incorporates digital technology to maximize efficiency, increase manufacturing capacity, and build processes that create value.

As plants adopt technological concepts, customers have come to expect a higher level of service. Businesses remain competitive via digitizing manufacturing plants and reap the following benefits.

Productivity and efficiency gains

Operating a facility can be centralized, improving the ability to oversee all lines and take control where needed. When working more centrally, the human workforce can monitor the entire factory at once, without having to be present on the factory floor.

A PwC report notes that companies investing in factory digitalization to drive efficiency are expecting revenue increases of 12% over the next five years.

Accelerated innovation

It is evident that digital manufacturing technologies accelerate innovation in both design development and processes.

With the colossal strides being made in CAD systems, the question is not whether a manufacturer should adopt them, but rather how quickly.

Traceability and product genealogy

Modern technology enables automated traceability by recording data that is gathered from constantly monitored machine parts, product components, and production lines.

Information on each component and product, including inspection results, assembly details, and time spent at each station, is recorded from end to end.

Connectivity

Improved connectivity creates three opportunities for manufacturers:

- The entire supply chain becomes digitized, eliminating variability in product creation. Every product is produced to the same standard of quality.

- Implemented tools and platforms enable the workforce to utilize newer technologies, boosting their efficiency.

- Connectivity identifies further opportunities for improving processes. Through smart data analytics, manufacturers can question how they can optimize factory output.

Improved quality

The benefits of digitalization can fundamentally transform every aspect of the business.

With data from connected equipment, manufacturers stand to gain a new level of operational visibility across sites. This is the foundation for significant operational improvements, such as the implementation of predictive maintenance programs. Factory digitalization detects and prevents quality problems by finding and addressing equipment issues sooner.

Data-driven and paperless decision making

Real-time business information enables quicker decision making, thrusting companies ahead of their competitors through faster reaction time to market volatility. When considering the dynamic nature of a shop floor, and the number of stakeholders who need to collaborate, the benefits of paperless manufacturing extend to multiple operational areas and hold potential to transform operations.

Paper and Excel sheets are costly, slow to file, and highly prone to human error. If data is not available in quickly-extractable digital form, decision making is slowed, costs increase, and the market advantage is lost. Real-time reporting and monitoring through data unification will enable data-driven decision making.

Reduced downtime and cost

Keeping a manufacturing plant running for longer, without breakdowns, requires regular predictive maintenance. Connected devices send information from to workers that a machine requires repair. This reduces the need for constant on-call maintenance workers, since factory supervisors can plan machine maintenance. Reduced downtime inevitably leads to reduced costs and increased profits. Not only can you determine which equipment is using the most energy, enabling changes to reduce energy costs.

Factory digitalization doesn’t always require substantial investment in sophisticated machinery – it may be possible to digitally connect existing manufacturing equipment. Connection provides data that can be used to correctly estimate faults, avoiding human error when assessing factory hardware.

Improved safety management

Safety is an integral part of lean production, and how manufacturing companies manage safety is changing.

Many are employing software to enhance their safety programs, which improves documentation, incident tracking, as well as the entire safety culture. Digitalizing the management of safety instructions enables quick uploading of existing instructions and the collection of digital signatures – no more paper-based processes.

The challenges in implementing factory digitalization

According to the Annual Manufacturing Report by PwC, manufacturers who do not digitalize may see profits fall as much as 5.1% compared with similar organizations in their sector.

Legacy platforms, misaligned technology, departmental workarounds, and other siloed departments all contribute to this profit erosion. Factory digitalization overcomes these hurdles.

The key challenges include:

- Choosing the right technology

- Reskilling and upskilling workforce

- IT/OT security

- Transition from the traditional to the servitized business model

Choosing the right technology

Technology complexity, its integration within legacy systems, and implementation costs are seen as obstacles when building a factory of the future.

Another challenge, especially for global manufacturers, is keeping sensitive data transparent, available in real-time, and secure.

Because of perceived implementation costs and effort, many manufacturers try to avoid a full digital transformation, only partially changing their factories.

These small-scale solutions will deploy faster and bring instant results. However, long term, they create even more complex legacy systems that impact a manufacturer’s future potential.

Reskilling and upskilling workforce

The human aspect of factory digitalization is often underestimated. A poor understanding of modern technology can significantly impact digital transformation and even the implementation of smaller digitization projects.

The eradication of multiple shop-floor roles due to an increase in automation means that future workers must be more digitally skilled in order to work in this new digitized business environment.

The real challenge is the lack of people able to handle digital technologies on the production-plan level. No one knows what future skills the manufacturing sector will require since it is changing so dynamically.

Employees and managers who embrace the digitized mindset will be critical for future performance.

IT/OT security

Greater connectedness in the globalized world has led to increased attacks on IT systems. This threat is real due to the growing adoption of sensors and other devices connected via the Industrial Internet of Things (IoT).

Industry 4.0 has only increased the likelihood of attacks due to data gathering and transmission via IP (Internet Protocol). Data must be protected when transmitted, whether within factory walls, to third-party data processors, cloud analysts, or supply chain partners.

IT/OT system security in the integrated and online environment is often cited by manufacturers as one of the main challenges when adopting factory digitalization. An integrated and connected shop floor, as well as a connected supply chain, are seen as significant threats to a company’s security and safety.

Some manufacturers move their systems to the cloud to obtain a more flexible, yet competitive advantage. Others worry the cloud can be hacked and opt for on-premise platforms. Any manufacturer keen on embracing a digital future must understand that the threat from cybercriminals is an inevitable part of digital transformation. Recognizing the threat, though, is not the same as doing nothing about it. Modern cyber defenses are sophisticated and effective.

Changing from a traditional business to a servitized business model

Transitioning from a traditional business model to a servitized one is hard for many to accept. A servitized business model requires a complete change in mindset, focusing on value instead of cost.

Tackling the digitalization challenges in manufacturing

Even well-intentioned plans can go awry without knowledgeable execution or partners who understand your industry’s intricacies and best practices. To avoid these fears, manufacturing companies can best prepare themselves for digital transformation by ensuring they tackle the following critical issues.

Have a real strategy in place

Factory digitalization should be in line with business strategy. To ensure processes deliver business value, clearly define expectations for change. By defining needs, you will be able to earlier identify and prioritize potential barriers.

Drive top-down digitalization change

Ensure that all senior people at the company commit to factory digitalization. Having fully digital factories is a long-term strategy, with an ROI of two to five years. That requires top-level investment decisions and changes in the business ecosystem.

Engage the right collaborative partner

Learn as much as possible from others. Seek out case studies of other successes within your industry or the competition. A digital transformation partner will have plenty of scenarios of how they transform companies. along with learnings.

Use tools effectively

Technology is only a tool. Without the proper use and analysis, it will not be as effective. Ensure you map the exact order of actions, roles, and the technology needed in the digitalization process.

Empower manufacturing through data confidence

Quick decision making is a pre-condition for success. Digitalization enables faster decisions made in real time.

Adopt rapid, flexible integration

Digitalization gives maximum benefit when technology and processes are integrated into existing systems.

Focus on cybersecurity from day one

Reliance on IP connectivity makes adopting cyber protection technology a must. Today, nearly all digital manufacturing technologies contain such protections.

Develop a business model that adds value

Factory digitalization is an opportunity to create new business models like servitization, meaning a shift from a product-centric business model to one that is service-centric.

Manufacturing-as-a-service offers benefits for manufacturers who compete with low labor-cost countries. Service-based products help maintain the customer base.

Upskill and retrain workforce

A manufacturer capable of scaling will need to reskill and upskill their staff by developing better quality training programs that teach real digital skills.

If in-house training capabilities to train aren’t present, collaborating with similar companies can help fill the skills gap required.

Retrofit and modernization of legacy equipment

By digitally retrofitting a factory, manufacturers can get ample benefits:

- A digital retrofit minimizes workflow disruptions, allows greater production flexibility, and centrally tracks production data.

- Digital retrofits are less expensive than purchasing or developing new machinery and eradicates machine downtime.

- Digital retrofits provide access to real-time data, which is used to improve and monitor product quality.

- By digitizing legacy machines, users can monitor their condition and determine what impacts their regular upkeep – resulting in the ability to predict when maintenance is required and reducing downtime.

Factory digitalization case studies

As companies digitalize factories, smart organizations that embrace digitalization see the greatest competitive advantages in the market.

At Proekspert, we have demonstrable experience delivering factory digitalization and other associated solutions to a broad range of business sectors.

The case studies below will give you a better understanding of the skills and expertise we have, and the benefits we have brought to businesses worldwide.

Read more about our clients’ successes.

Share your challenge with us

Factory digitalization requires a specialized skill set. Share your factory's challenge with us, and let us guide you on your digitalization journey.

Thank You!

Your message has been sent. Our team will get back to you as soon as possible!